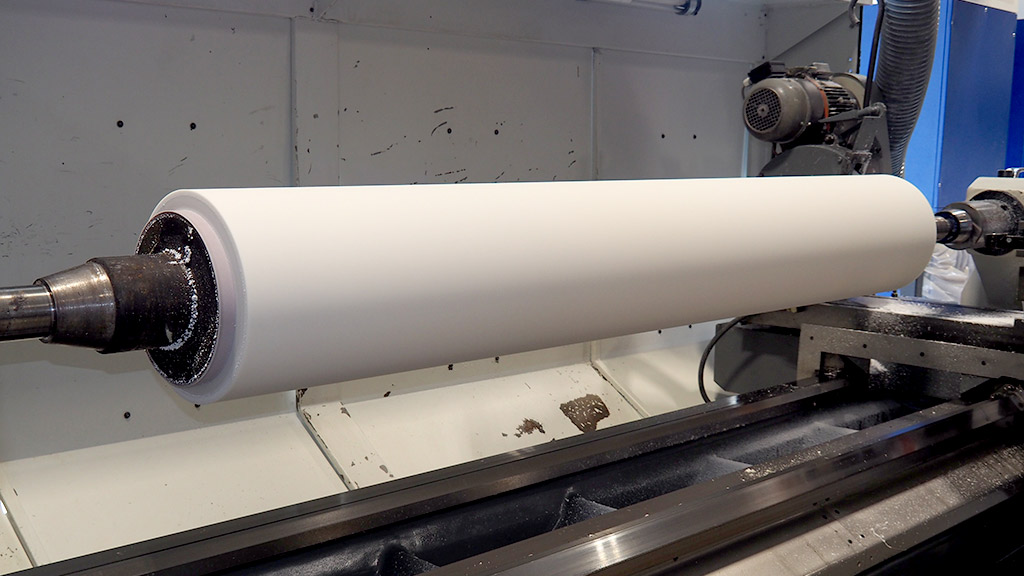

„Letting things slide skilfully is inevitably not the worst,“ claims the five-strong asma large roller team. Large rollers, varnishing rollers, star wheels, forklift wheels, Vulkollan wheels and much more are used in this department for industrial use. Turned, ground and prepared for delivery. The necessary know-how in processing must not be missing here.

The right choice of material is also a decisive factor in application and painting roller coatings.

These roller coatings are usually offered on the basis of rubber materials (EPDM or NBR). However, the right choice of material is crucial for a satisfactory result. Polyurethane differs from the rubber materials mentioned in the following special features: Excellent wear and cut resistance, very high resilience, high elasticity and excellent resistance to paints, solvents and oils.

In addition to the application and painting rollers, Asma also produces coatings for glue application rollers for existing and new roller bodies. The special features are high resistance to edge marks, the possibility of painting profiled and structured workpieces, as well as oil and solvent resistance.

Info:

Easy Pren® application rollers made of polyurethane for paint and oil application

Areas of application in the wood industry for paints and oils

Furniture, parquet and vinyl floors, doors, MDF board products

Special features:

Extreme deformability and flexibility, bevel and radius coating possible, structure-free roller surface for high-quality lacquer surfaces, cut resistance to sharp workpiece edges, a roller surface suitable for lacquers and oils

Available from asma:

- Hardness range: 10-53 ° Shore A, for Bürkle, Cefla, Hymen, Barberan and Wemhöner machines.

- Maximum diameter: 600 mm

- Maximum length: 4000 mm

- Maximum part weight: 3 to

- Customer-specific surface finish including possible grooving

Further areas of application:

Metal, plastic & glass surfaces