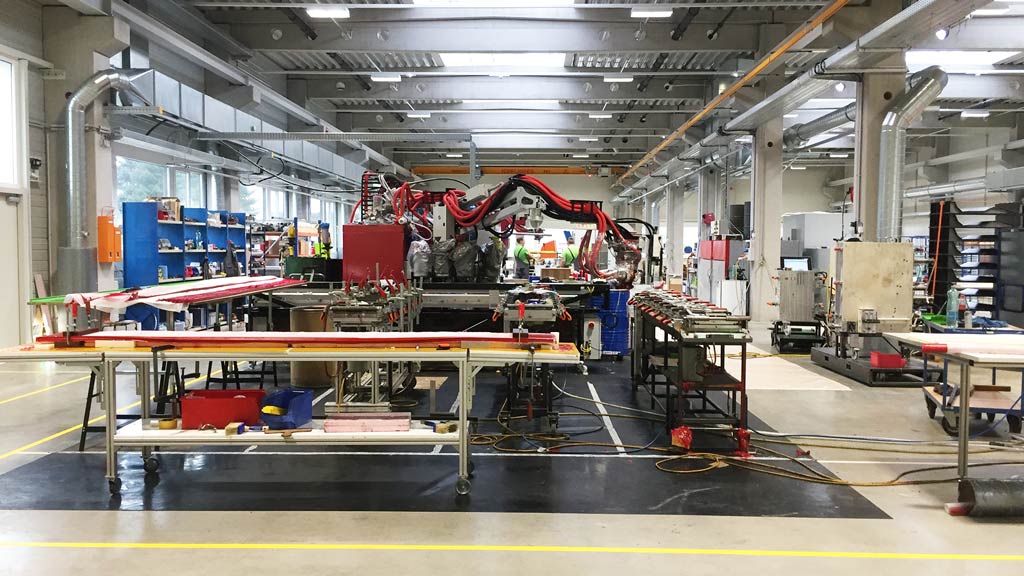

The construction containers are gone, excavators, construction machines and the entourage of construction workers have been withdrawn. The freshly paved traffic areas are waiting for the snow. The machines are set up inside the new hall, and large rearrangements are the order of the day.

We look forward to 2000 m2 of production space, 1000 m2 of storage space for raw materials, a new technical center and an energy center with a new transformer. The fully automatic building control and building data acquisition, the modern ventilation system with heat recovery, heat pump and recooling register support the economical use of energy.

The existing building was also heavily rebuilt. A good 1000 m2 of storage space with new floors, new LED lighting, completely renovated. The delivery with delivery building, warehouse office and incoming goods inspection, the logistics axes through the building have been widened for the transport of bulky goods without internal reloading.

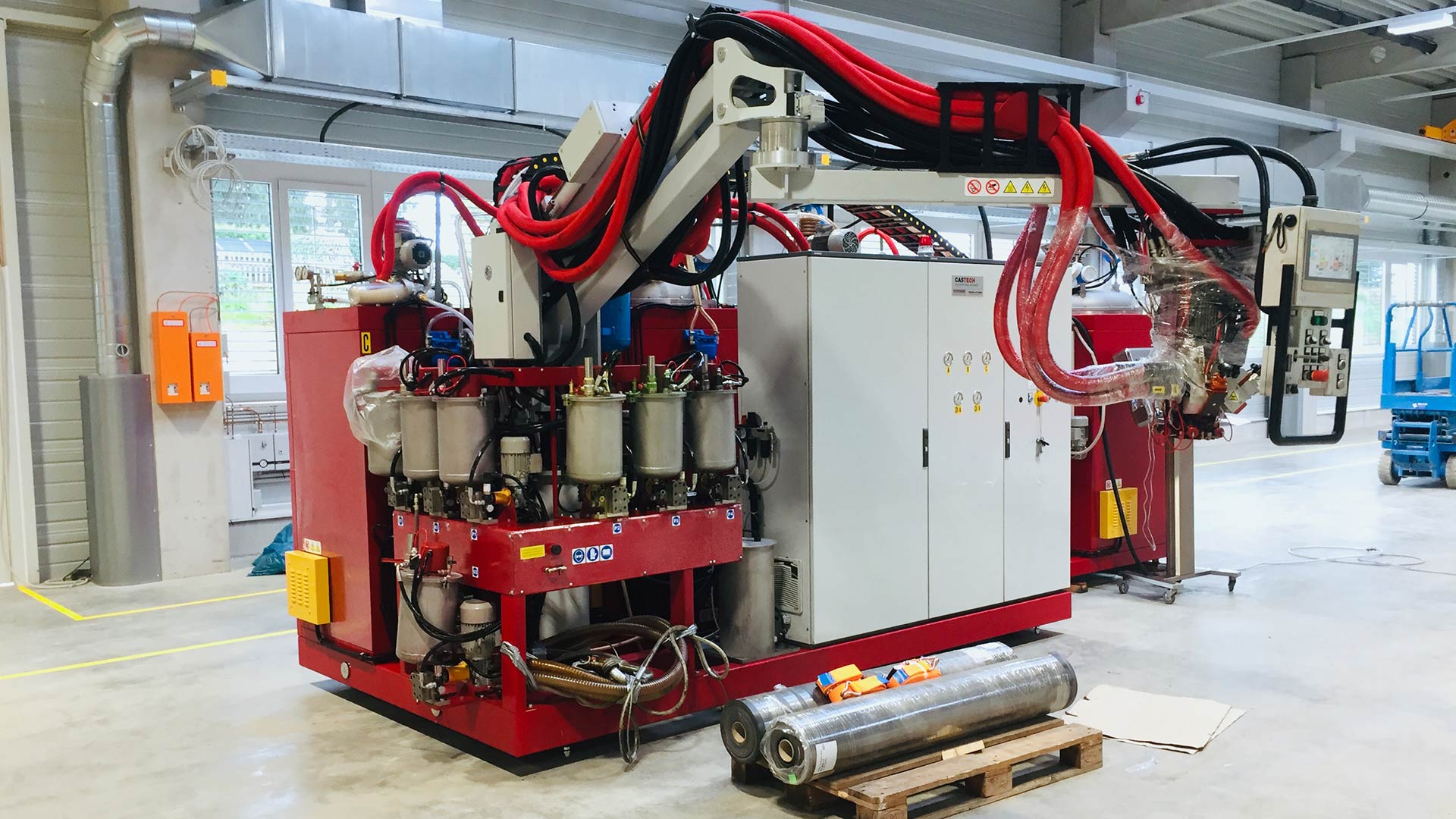

The large rollers are already being processed in the new building, and the coating roller foundry has its own separate area.

With the expansion of the production area, new ovens for preheating and tempering rollers as well as material preheating were put into operation.

Further machines are on order and will contribute to the expansion of our manufacturing capacities and manufacturing possibilities in the next few months with new technical possibilities.

Last but not least, a digitization focus rounds off the investment program, which is unique in the history of asma.

Thus, we are looking confidently into a hopefully soon corona-free future, well equipped for the expected economic upturn.

At the end of a challenging year we wish all our customers, business partners and friends a Merry Christmas and good luck and health for the New Year.

GF Thomas Brandeis