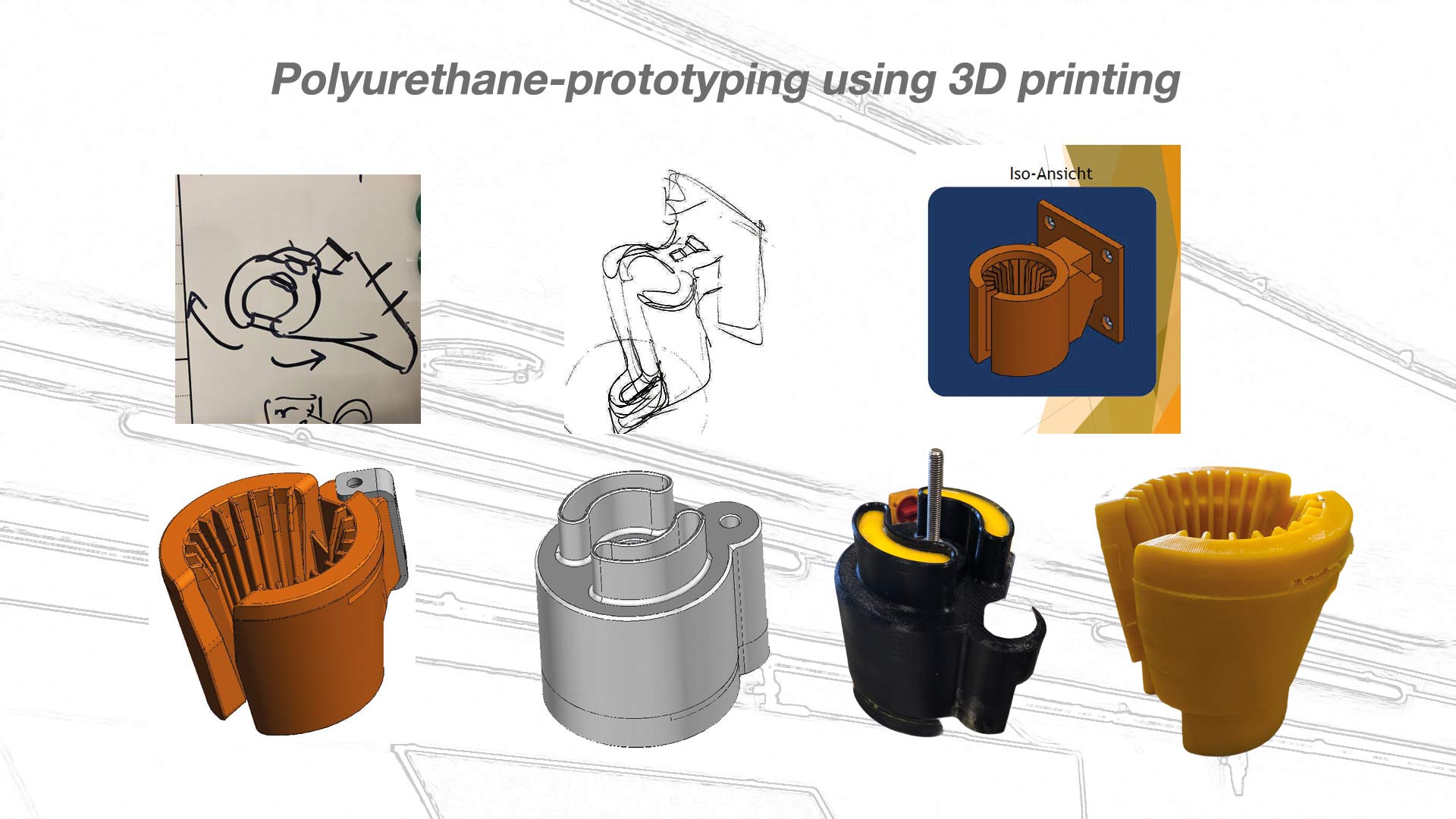

Prototype-production using 3D printing is already in discussion now for quite some time. Asma, as a polyurethane processor, is also increasingly approaching customers with corresponding inquiries. One thing they have in common is the desire for flexible and cost-effective production of complex prototypes without having to invest in laboriously milled metal casting moulds. Many of these products are still in development and therefore do not yet have their final geometric shape.

So an ideal playing field for 3D printing?!

At first glance, it seems that way. However, the currently available material and processing qualities of printable polyurethanes do not (yet) meet the high standards that we at asma have set ourselves. To get around this problem, we decided to go the other way around.

Instead of having to compromise on material quality, we produce the casting moulds using 3D printing and produce the prototypes in tried-and-tested series materials. This means that even complex parts can be produced in series quality at comparatively favourable conditions.

The samples produced in this way are therefore more than just visual samples and can be used for experiments at an early stage of development. Compromises only have to be made with the surface requirements. One of those projects where the approach described has recently been used is a new type of tool holder from the Toolprotect brand for one of our customers.

Toolprotect has fully committed itself to the motto „Maximum protection for man and machine“. This tool holder is a new product that will come onto the market in 2022 and is used to enable components and tools to be stored safely in sensitive work areas.

A prime example of the synergy from the product idea through development and prototyping to series production in the so diverse world of polyurethane.

Do you have a technical task to accomplish with a flexible elastomer component according to the most modern aspects of material and production technology, but still no satisfactory solution? We are happy to accompany you on the path of your product development – our team in technical sales looks forward to your special task.

A prime example of the synergy from the product idea through development and prototyping to series production in the so diverse world of polyurethane.

Mario Weninger