PUR materials with a hardness of 30 Shore A are not always easy and are therefore not offered by all manufacturers and processors. Required properties such as hardness stability over time, free of plasticizer migration, solvent and hydrolysis resistance, acid and alkaline resistance do not simplify this topic. At Asma, we have been operating with this issue for a number of years. With three fundamentally different formulations, we can cover almost all customer requirements for ultra-soft polyurethane materials.

Easy Pren 10 Shore A:

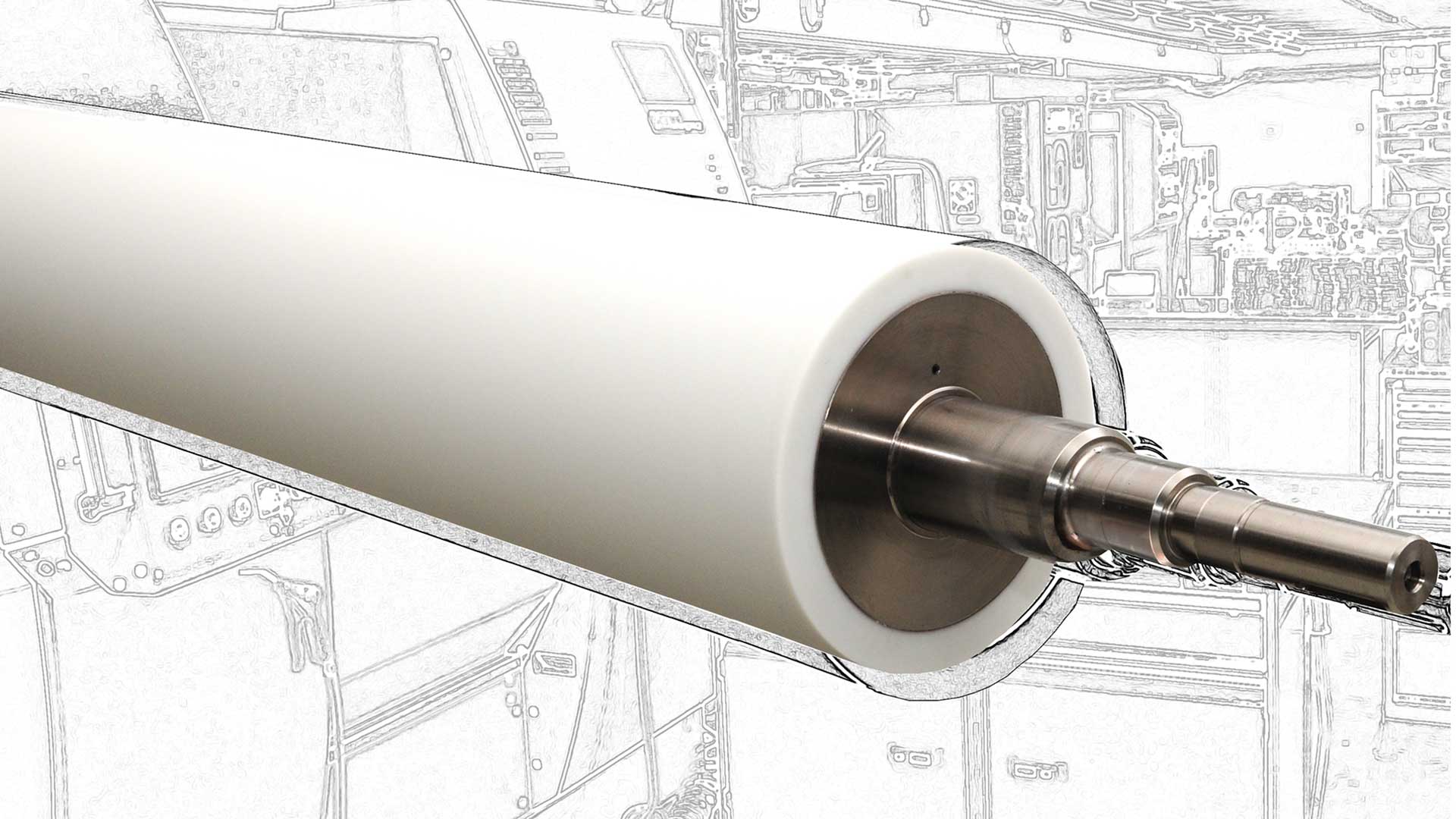

Our 30 Shore A Easy Pren roll coverings, which were previously considered to be very soft and highly durable, have revolutionised the paint job market in the roller coating process. These are used since many years for industrial surface finishing of furniture, door and floor surfaces. Due to the potential for cost optimization, new production processes as well as new workpiece surfaces at our customers, the desire for even softer and durable roll coverings was brought to us. Since 2019, we have been able to produce highly durable Easy Pren roll coverings with 10 Shore A in reproducible quality. The grinding process had to be enhanced, because these soft PUR materials were considered to be poor to non-grindable. Through a joint dedication of production and R&D, we have also succeeded in this. Since the market launch, we have received a lot of positive feedback from our customers. The 10 Shore roller covers have led to new possibilities in industrial roller coating process as well as new surfaces in the furniture, door and floor industry. On customer request, these Easy Pren roll coverings can also be manufactured with 15 or 20 Shore A.

AsmaGel:

Soft PUR- materials with a hardness of 10Shore A and a certain permanent residual stickiness on the surface are not entirely new. You are familiar in the private sector with anti-slip pads for storing mobile phones, e.g. in the car. The idea of Asma few years ago was, to make these types of materials usable for industrial applications at our customers. One of our focused areas of use is the application as a dedusting roller in the production of plastic and metal films. High-quality films must be cleaned before further processing or delivery of the smallest, adhering dust particles. Roll coverings made of AsmaGel can be used here to absorb the dust directly through the stickiness or can be released on even more sticky dust collectors. If too much dust has accumulated on the sticky roller surface, it can be easily cleaned with soapy water and the permanent residual stickiness reappears. AsmaGel is no longer measured in Shore A due to its low hardness, we use the underlying hardness scale Shore 00. As a guideline 50 Shore 00 corresponds to 5 Shore A. AsmaGel we produce with a hardness of 50 Shore 00 (very sticky) to 90 Shore 00 (almost sticky-free).

AsmaGel is also used for molded products or other coatings. The focus here is on the enormously high coefficient of friction and the shock-absorbing effect. With its wide range of formability and hydrolysis resistance, it expands our previous range of ultra-soft polyurethane materials.

Asmaprene H15:

This is our latest ultra-soft polyurethane material. With 15 Shore A, this has excellent acids, alkalis and hydrolysis resistance and is mainly used in pickling lines on roll coverings.