Polyurethane elastomers (PUR) are ideally suited as wear-resistant coatings for technical applications in industrial plants and machines. These are usually liquid and poured onto metal surfaces with the help of casting molds.

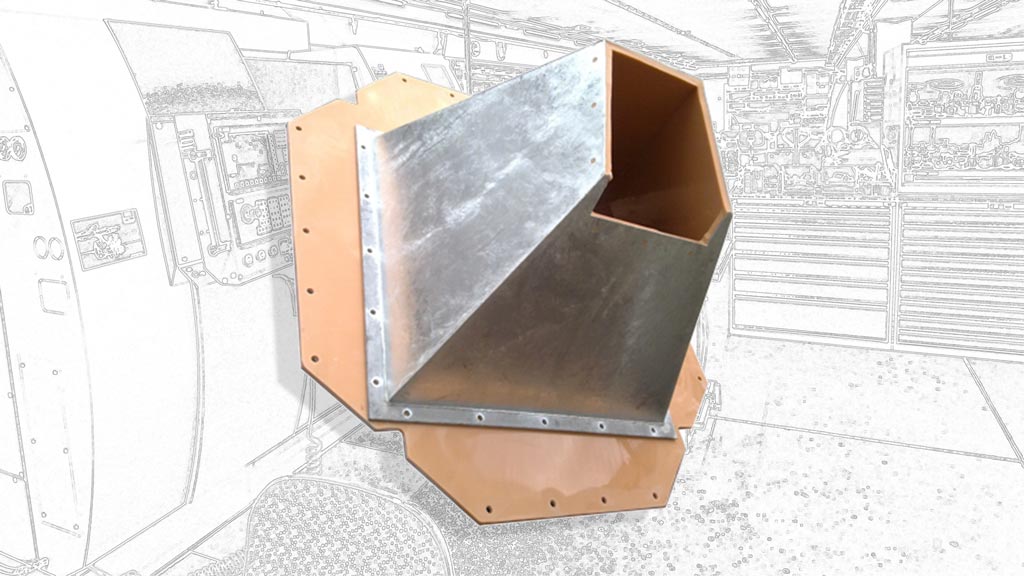

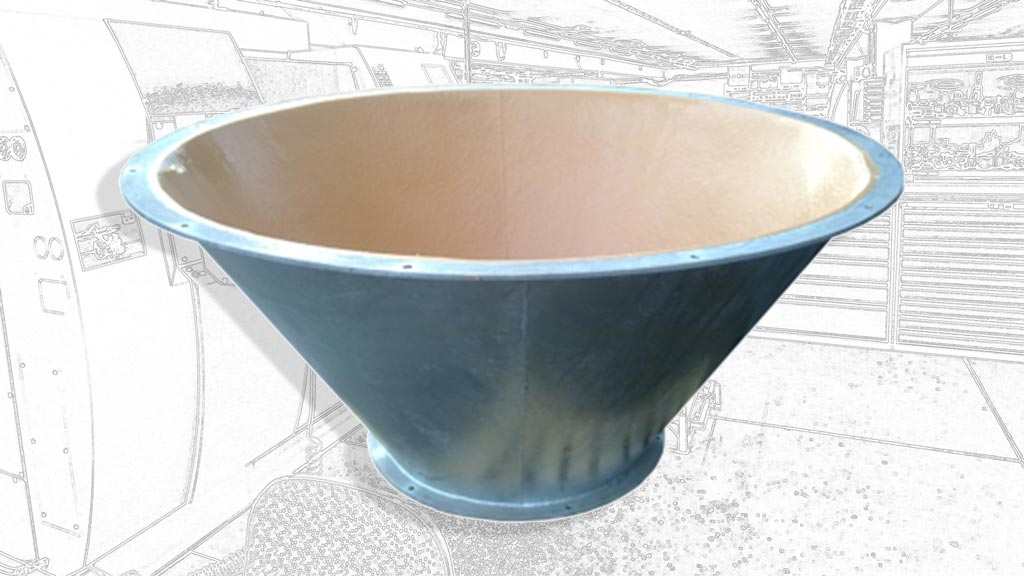

In the case of large-area coatings such as in tubs, troughs, conveyor troughs, transport containers, chutes and feed stations, the production of a casting mold is in many cases not economical.

A PUR spray coating is suitable for such cases. In this spraying process, a special, highly reactive type of polyurethane suitable for this production method is sprayed directly onto the (metal) surface to be coated without a mold. The polyurethane layer solidifies in a few seconds and forms a compact, closed and wear-resistant plastic layer. This means that coatings can also be applied to highly complex surfaces.

A major advantage of the spray process is that it is possible to achieve higher layer thicknesses on particularly heavily used surfaces. In addition to the other advantages, there is a seamless coating that does not allow wear and tear, and noise insulation.