At Asma, we have been manufacturing stretched screen mats (flip-flop screen linings) made of polyurethane for many years. In order to meet the diverse requirements and possible uses of the screening machines and their required screen mats, both the polyurethane materials and the manufacturing processes have been continuously developed during this period.

In order to ensure a long service life for the screen linings, the highest quality criteria are required, both in terms of mechanical properties such as tensile strength, tear resistance and abrasion resistance, as well as precision during assembly.

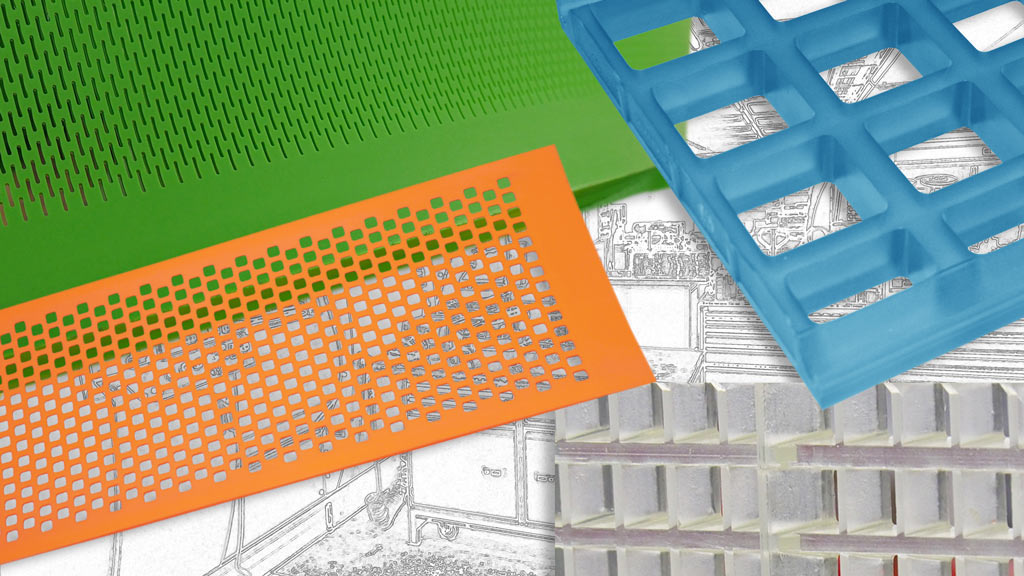

Several CNC-controlled punching machines equipped with the latest technology offer the possibility of producing freely programmed hole patterns.

Screen linings up to a length of 4000 mm and a width of 500 mm can be made up with a large number of existing punching tools.

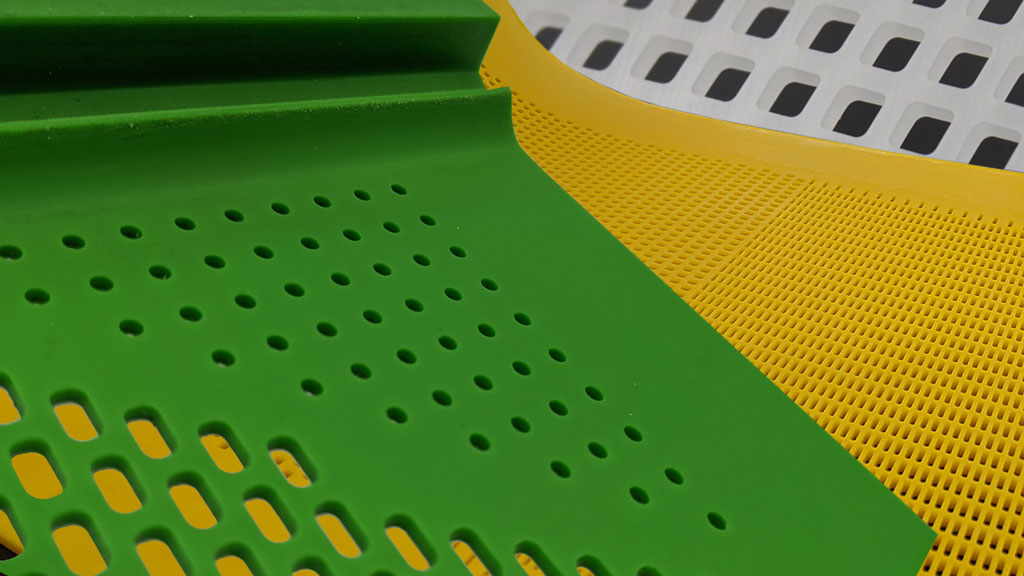

It is possible to punch almost any hole size and shape you want. In mesh sizes from 0.35 mm to 80 mm and as elongated holes, in rectangular, square, round or oval designs. Even unusual hole patterns and different mesh sizes on a single screen mat can be produced cost-effectively.

With screen mats made of different polyurethane materials such as AsmaScreen, AsmaPrene, Asmathane and Vulkollan®, we cover all conceivable requirements for different operating conditions. Highly wear-resistant and long-lasting with the best suitability in terms of hydrolysis and microbe resistance, acid and alkali resistance, electrical conductivity, low temperature suitability and temperature resistance up to 100 ° C.

The spectrum of screening tasks ranges from sand, gravel, minerals to ores, coal and animal feed to special tasks such as household waste, sewage sludge, incineration slag and a wide variety of recycled goods as secondary raw materials. The locations around the world, from the polar circles to the equator, are now standard for ASMA.

Asma screens can be designed for machines from all renowned manufacturers, both for screwing and clamping systems. We achieve short delivery times by constantly stocking blank screen mats, which are tailored to customers and orders.

We are also happy to accept special requests.

More information on the website:

https://asmapur.polyurethane.at/moulding-parts-sieves/

https://asmapur.polyurethane.at/polyurethane-flip-flop-screen-mats/