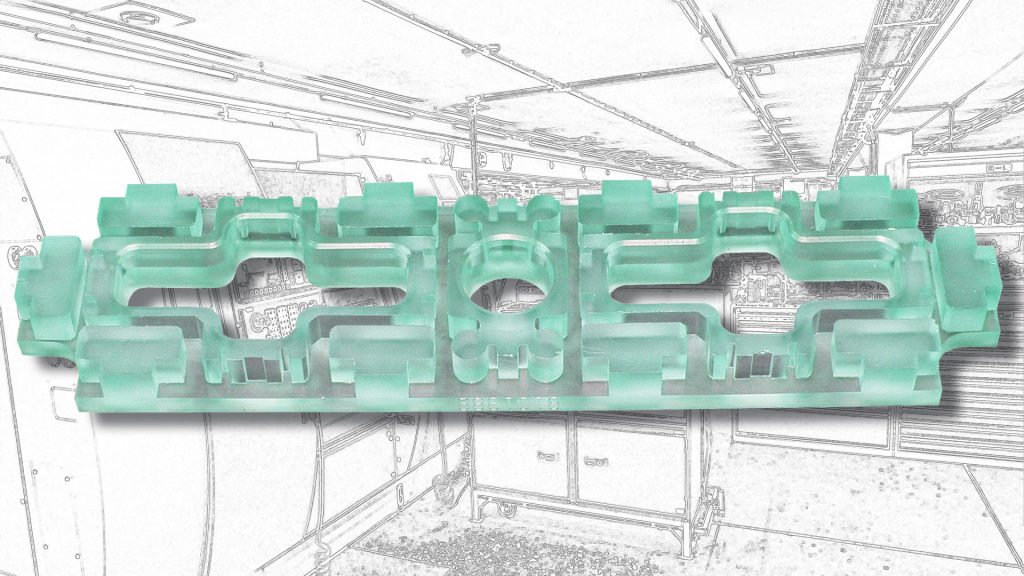

Moulded sealings

PU moulded sealings from Asma exhibit good temperature resistance, hydrolysis resistance, acid and alkali resistance in different Shore hardnesses

Properties

- Moulded sealings made from PU are highly resistant to wear and, according to Shore hardness, can be moved and deformed in many ways.

- High stress without a loss in density effect is possible

- Suitable for the application in liquids as well as in gaseous environment

- FDA-approval, resistance to temperature, resistance to hydrolysis, acid- and lye-proof

Application

- The flexible processing possibilities are an advantage

- The sealing elements are considered independent since the operating pressure reinforces the sealing effect

- They are often used for hydraulic and pneumatic components

Available at asma

- Customized moulded parts or coating of carrier part

- Hardness ranging from 25° to 95° Shore A

- Single pieces to large-scale production

- From very small parts to bigger sealings dependent on the contour

- Internal mould construction allows for a flexibility in changing and adjusting

- Production of the components using vacuum casting is possible

- Making a choice, after careful selection, for the suitable PU type according to the field of application

- (food industry, temperature, hydrolysis, contact with special acids and lyes, certain oils …)