Sieves

Highly abrasion resistant sieves – sieve mats, sieve linings, flip flop sieves, flip flow sieves

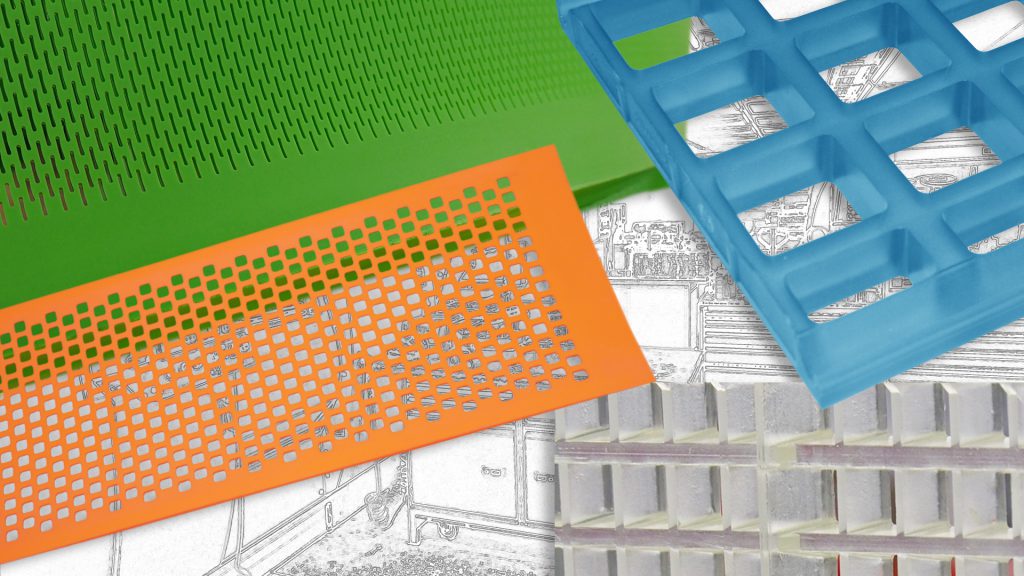

Sieves, flip flow screens, screening mats, PU screens

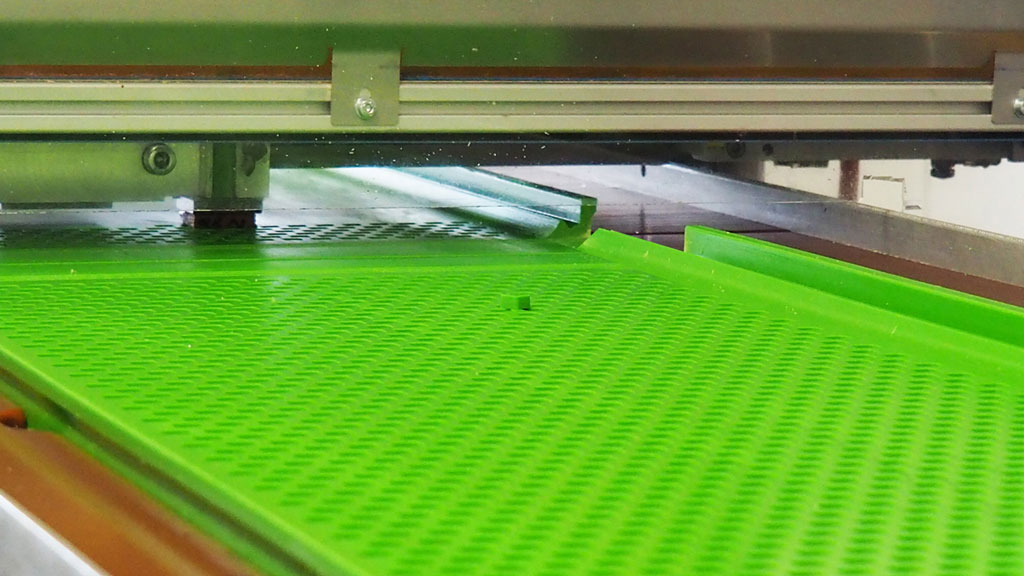

We are a manufacturer of high-quality polyurethane replacement screening mats for all flip-flow screening machines. Screens made of AsmaScreen, AsmaPrene, Vulkollan® and Asmathane are designed for different operating conditions, highly wear-resistant and durable. We realize short delivery times for machines of the renowned manufacturers by constantly storing blank mats, which are assembled order-related. Both dimensions and the perforations are manufactured in-house customer-specific or order-related. We are also happy to accept special requests for flip-flop sieves.

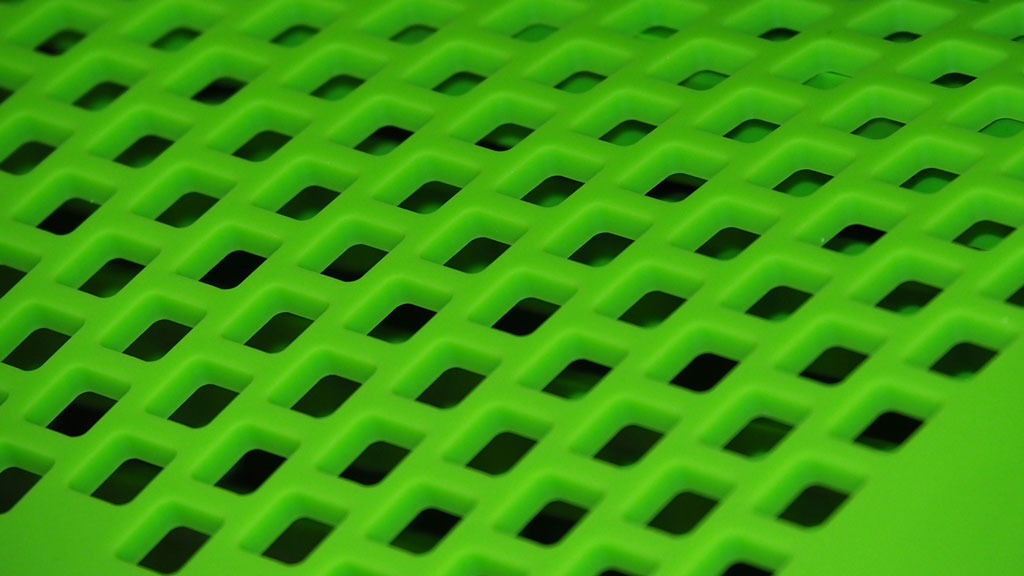

Flip flow sieves made of polyurethane are:

- Highly resistant to wear and abrasion

- Self-cleaning (even with moistened and sticky material)

- Quick and easy replacement

- Noise reducing

- Prevent clogged particles

- Suitable for wet and dry screening

- Suitable for wet and dry screening

- Corrosion resistant

- Depending on the polyurethane material version temperature-resistant up to 100°C, acid and alkali resistant, microbe-resistant, hydrolysis resistant.

Application

Classification of sand, gravel, crushed stone, minerals, ores, coal, used glass, feed, biomass, construction & demolition, secondary raw materials, incinerator slag, compost, sludge, construction rubble, dewatering and dedusting of bulk materials. The flip flow mats are used in vibrating mining screens, quarry screens, compost and waste treatment.

Available at asma

Flip Flop sieves, screen linings, screen mats, screen decks made of Polyurethane, independent from different machine manufacturers and fastening systems

- Maximal width: 500 mm

- Maximal length: 4000 mm

- Thickness: 1-8 mm

- Hardness: 80-93 Shore A

- Customer-specific perforation 0.35-50 mm