Troubleshooting@asma – solving problems and developing results

The worldwide use of Polyurethane materials requires special measures in some cases to optimize a product. Extreme, climatic conditions, long transport ways overseas and different exposure scenarios in other countries also put a burden on even high-quality Polyurethanes, when not adjusted and sufficiently tested under a range of circumstances.

It is quite common that such requirements also demand a change in the product itself to meet the legitimately high expectations of our customers.

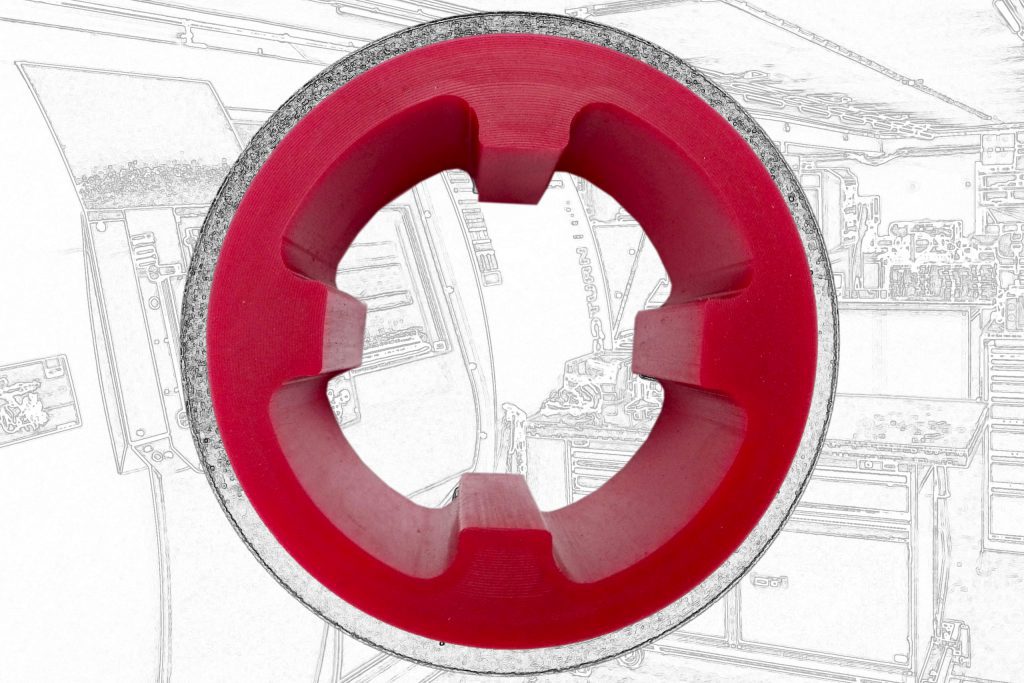

A good example is a sealing product in the which is subject to harsh climatic and application-specific conditions. A feedback of our customer that after the winter, with a lot of variations in temperature, the sealings had an exceptionally low service life, required us to analyse this problem together with the client. After many test series, we assessed how the product reacts to different conditions such as snow, rain, heat and frost, and how that changes with the chemical characteristic of the material.

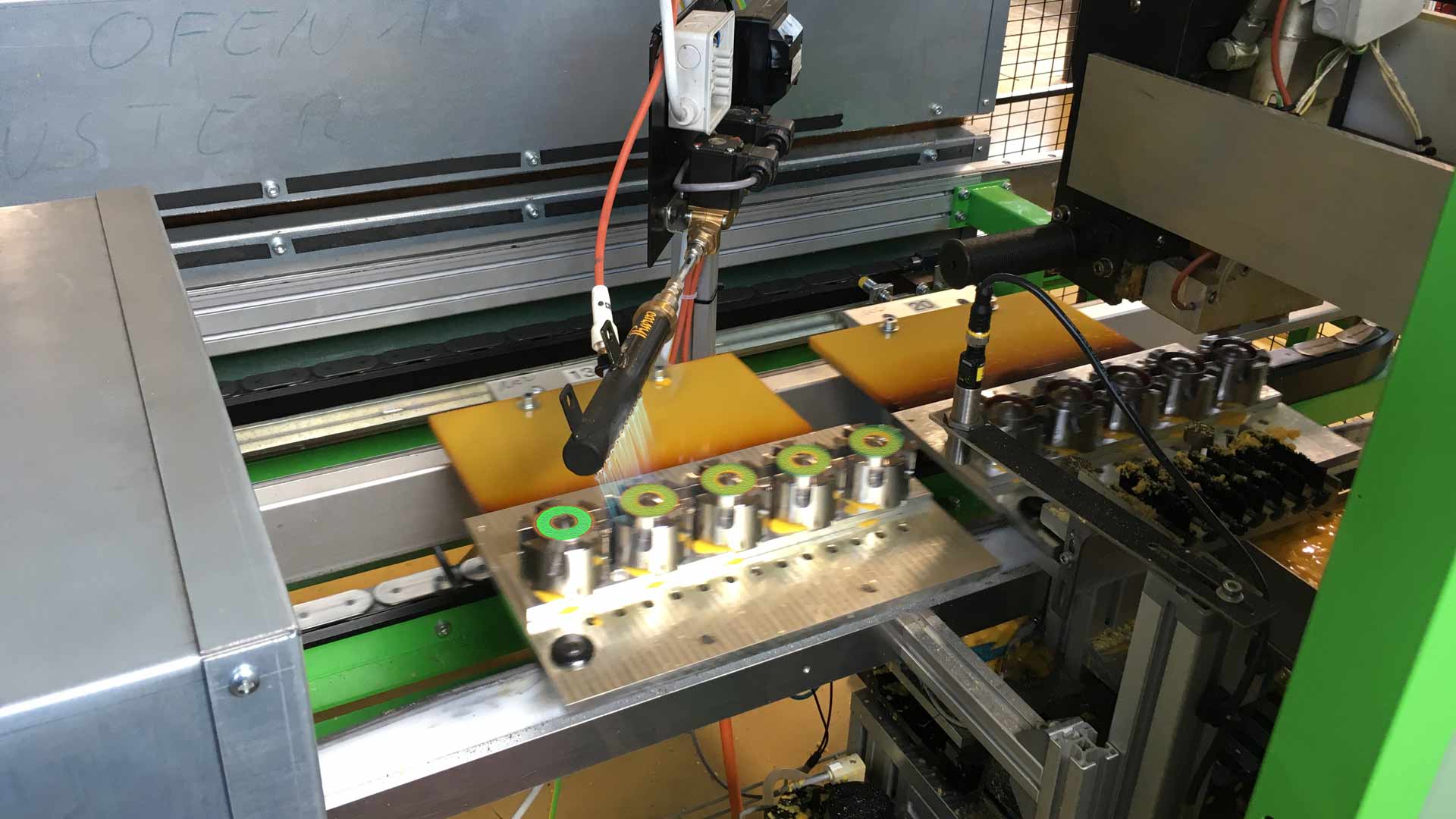

In a phase of optimization, improvements for any climatic conditions were made. At the same time, the process security was enhanced, and reproducibility was facilitated by creating a fully automatized production.

Applying specific troubleshooting, we could achieve a customized solution to shift from the production by hand to the fully automatized serial production with high reproducibility and process safety.