The production and disposal of plastics are very often cited as the causes of climate change and its negative consequences. Although plastic has become an integral part of our everyday life, as a manufacturer you can pay attention to a good sustainability record.

The production and disposal of plastics are very often cited as the causes of climate change and its negative consequences. Although plastic has become an integral part of our everyday life, as a manufacturer you can pay attention to a good sustainability record.

The responsible use of resources in production and the research and development of new processes and ways to improve the sustainability of production are very important at asma. In the following we present examples that have already been successfully implemented in production:

⇒ With the current manufacturing processes, each plastic part produces a certain amount of residual material that cannot be used for the product itself. However, in order to still be able to use this residual material sensibly, a number of projects have already been implemented at asma in the past under the motto „from residual material to recyclable material“. For example, in production, some of the residue is already granulated and reused. Materials for which this process is not suitable are passed on to specialist companies that use the waste in other areas of application.

⇒ The solvent DBE (dibasic ester), which is used to clean the casting machines, is distilled and reused.

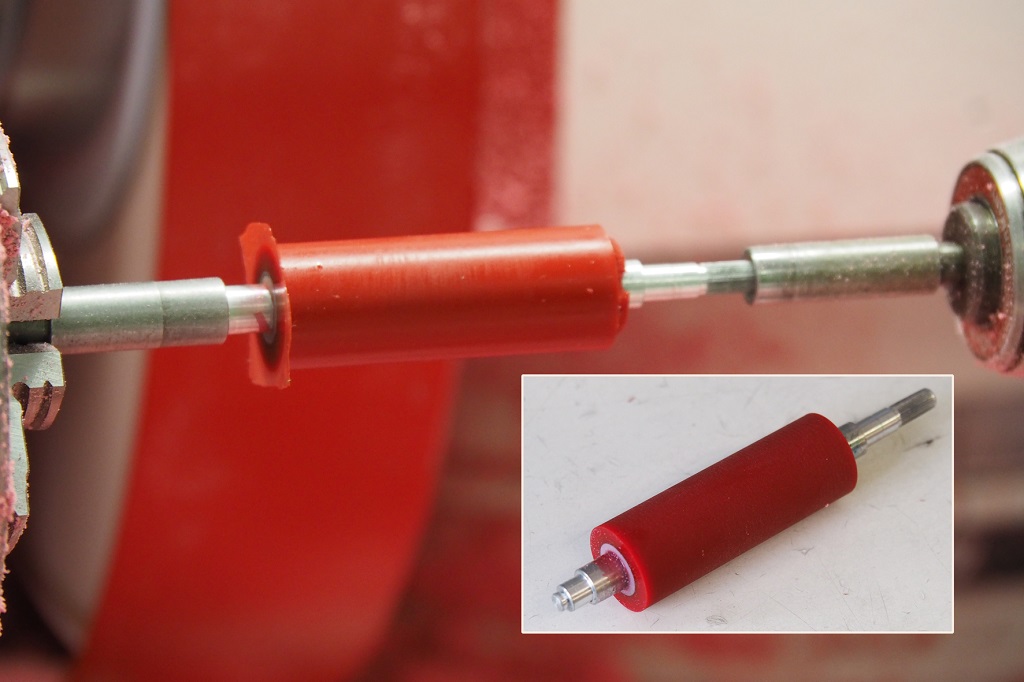

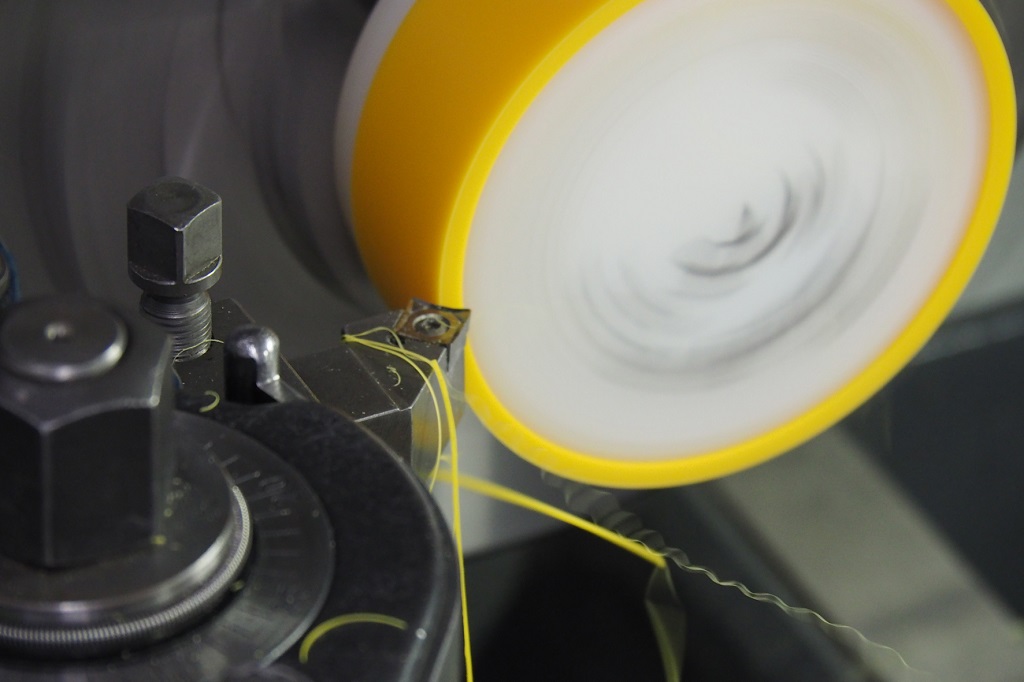

⇒ We have been offering our customers the re-rubber coating of rollers for many years. This means that the old cover is removed and the existing roll core is recoated. This has the advantage that the roller core can be used several times.

This is just a small part of our sustainability portfolio. asma is constantly working on further projects in order to be able to manufacture the products as environmentally friendly as possible.

Further projects on the topic of „Sustainability at asma“ will be presented in further blog posts.

A report by Dipl.-Ing. Adele Brandeis (data analyst / software development) in cooperation with Günter Braun (waste manager) and DI Dr.techn. Patrick Steinbauer (research / development)