Marlene Hoebarth

asma quality check

The first thing I do is start the dynamometer shortly before six o’clock. Depending on the development specification, roles are tested for their resilience and the results must be logged. This test bench is reloaded approximately every four hours.

In the first 2 to 3 hours I then appraise order by order to check the parts for hardness, dimensions, color and much more. (according to the sampling plan) for any deviations. Depending on the result, the orders are either approved or further steps are taken if errors are discovered. In the second case, good cooperation with the casting department and the responsible people is very important.

When I then come to my office, one or two mould approvals are already waiting for me. A so-called test casting, from a newly manufactured mould, which has to be thoroughly checked, can sometimes take an hour or more. There is hardly any room for error. This has high priority, because behind every test casting there is an employee who wants to start production.

In the meantime, I have to re-equip the dynamometer, issue the acceptance test certificates for outgoing goods and process the daily incoming mail.

Another task of mine is temperature management. Completely tempered parts are brought to the outgoing goods inspection, the remaining parts are rearranged and assigned to their correct place.

Throughout the day you go from one task to the next.

It is a very varied and – but in a positive sense – demanding work. For this reason, I am glad that I have been supported by my dear colleague for a few weeks. As my pregnancy progresses, it is becoming increasingly difficult for me to carry out my tasks at the usual pace.

In Verena Mayrhofer I have found a representative who has technical understanding and a feel for the material. Now I can calmly prepare for my expectant role as a mother. A new task and challenge that I’ve been looking forward to since the first point on the ultrasound image :-).

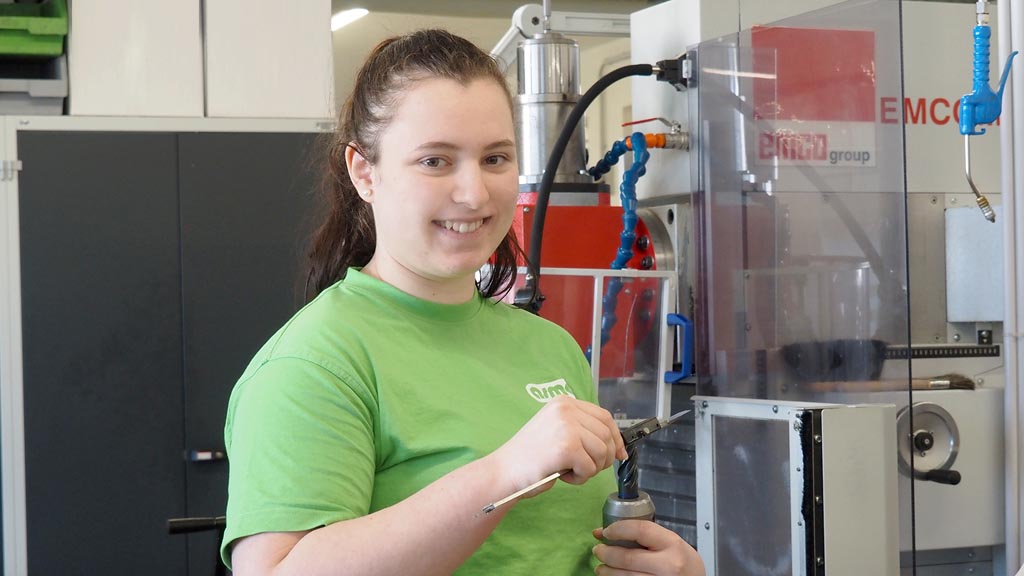

Who is Verena Mayrhofer?

Currently still training as a tool and automation technician in the asma mold making team. The final apprenticeship exam is planned for summer.

“I am looking forward to the new challenges that await me in the future. It’s a very varied field of work. During my apprenticeship I already got to know the company, the products and the materials. This helps me to master my upcoming tasks well. I would also like to sincerely thank Marlene for the good training,” says Verena Mayrhofer