Quality is the degree to which a set of quality characteristics meets certain requirements. Quality is the „degree of fulfillment“ of a product’s properties and characteristics, i.e. the extent to which specified requirements are met. The quality / quality management professional field describes the work processes behind it.

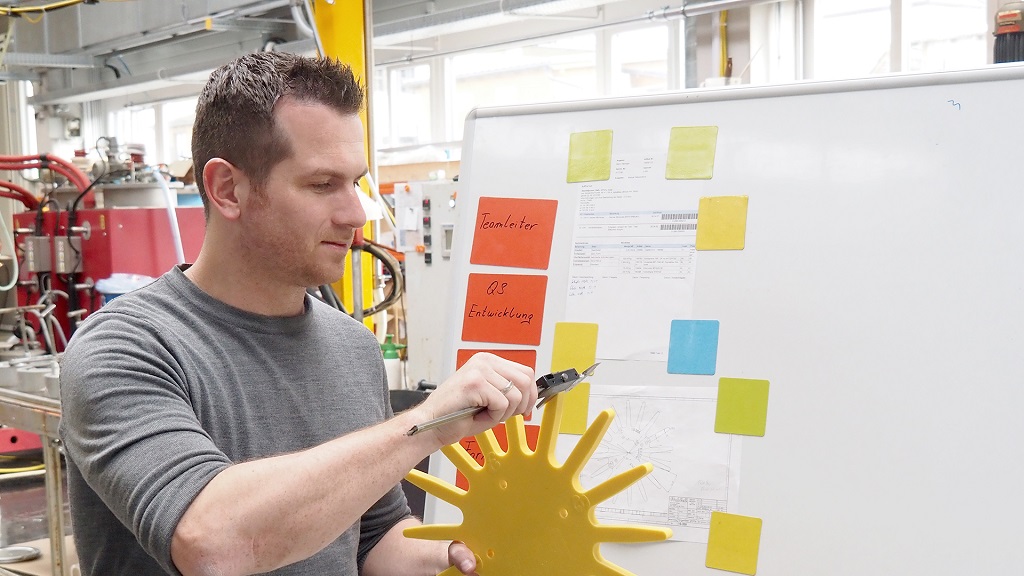

Thomas Bauernfried

quality management

The quality / quality management work area is very extensive and varied, since the basic building blocks for the highest possible manufacturing quality in production are laid with the first administrative work processes. As a service process, we are the point of contact for all quality-related questions, starting with the sales staff, the production line, right through to our customers and suppliers.

A normal working day includes numerous main topics:

-

- Sighting and interpretation of the quality-relevant key figures of the previous day in preparation for the Shopfloor-tour

- Processing of customer complaints (assessment of parts, initiation of measures, preparation of reports and statements, coordination of commercial and scheduling issues in the company and towards our customers)

- Participation in the Shopfloor-tour and processing of the quality-related topics that arise

- Participation in routine production and mold making meetings

- Processing of the quality-relevant daily issues of sales/administration-customer-supplier-production in the form of mail processing, component inspection, clarification of releases and special releases in accordance with customer agreements

- Processing of projects and product optimizations, in close cooperation with our development (error analysis, optimization possibilities for production problems)

- Maintenance and further development of our certifications according to ISO 9001 and ISO 14001 in all its facets (audits, documentation, etc.)

The classic quality assurance is carried out independently by my three colleagues in form of random interim inspections, outgoing goods inspection of the products produced and incoming goods inspection of raw materials and purchased parts to be able to ensure the best possible quality control in our processes.

Everyday work in the field of quality is extremely extensive and difficult to plan, since many issues arise suddenly and unexpectedly, and consequently numerous affected processes and/or customers are waiting for a decision on how to proceed. This can sometimes lead to pressure situations that require an objective, pragmatic approach and can also lead to unpopular decisions. It is a very varied field of work because continuous improvement and optimization is always the order of the day. After all, it is also our goal to constantly develop ourselves further and to be able to guarantee our customers the best possible part performance. Even if it is sometimes a rocky road, one grows (especially) with the challenges of mistakes or problems and must also see these as an opportunity to minimize one’s weaknesses.