At asma, PUR elastomers are always tailored to the customer’s requirements. Depending on the environmental conditions and mechanical requirements, a material type with a defined property profile and a certain Shore hardness is selected.

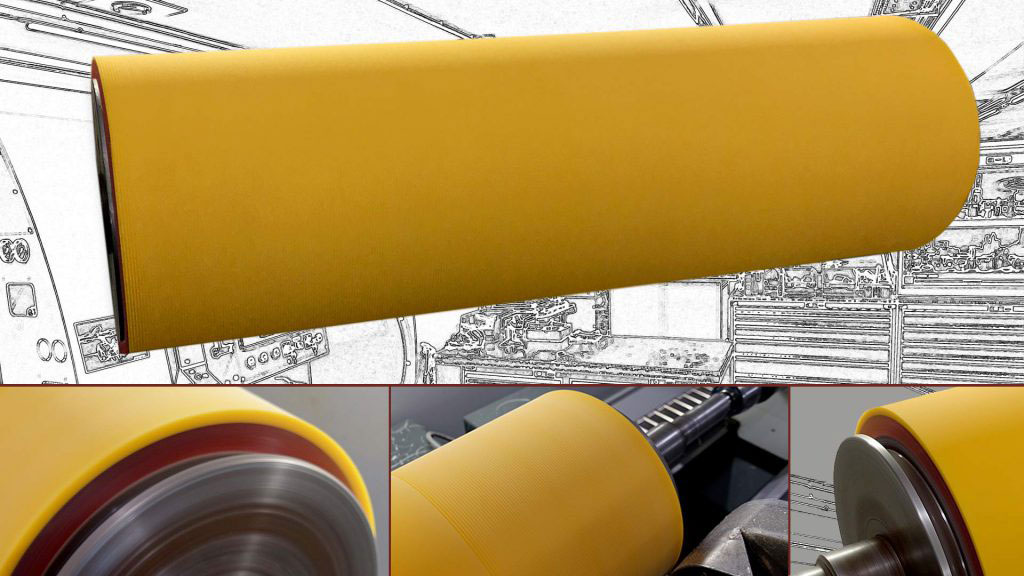

In many applications, however, combined properties of different hardnesses and material types are required. In order to meet these customer requirements, we at asma have been dealing with the combination of different hardnesses and material properties for years. After intensive development, we were able to expand our range to include roller coatings with a two-layer structure. The areas of application range from glue and paint application rollers in the wood industry to squeegee rollers for surface treatment in metal processing to painting applications in the film industry.

Often it is a combination of a highly deformable, highly flexible substructure with a wear-resistant polyurethane coating as a top layer. Roller coatings produced in this way withstand high deflections and at the same time reduce the line pressure due to the compressibility present. Both the workpiece and the machine are protected. The substructure can be made of cellular or ultra-soft PUR material in the range of 10-20 ° Shore A. The possible combinations are not limited to different Shore hardnesses. A combination of materials with different electrical properties is also possible. For example, an electrically insulating substructure with a work layer that is electrically conductive (antistatic). As diverse as the PUR recipes at asma are, the possible combinations are just as extensive.

General information on painting and oil application rollers

Varnishing rollers, hardness 8 ° Shore A

PUR elastomer is as soft as velvet but with a defined elastic force that allows the application of varnish even on pronounced undercuts. The formulation is based on a specially rolled-out prepolymer that is hardened using an organic compound from the group of alcohols and the appropriate plasticizer and filling material. This enables us to produce an extremely soft polyurethane with excellent resistance to various solvents and coatings.

In addition to the application- and coating-rollers, asma also produces coatings for glue application rollers. These are available as highly wear-resistant versions in the hardness range of 53—80 ° Shore A. The grooves necessary to achieve a precise amount of glue are applied accordingly to customer specifications.