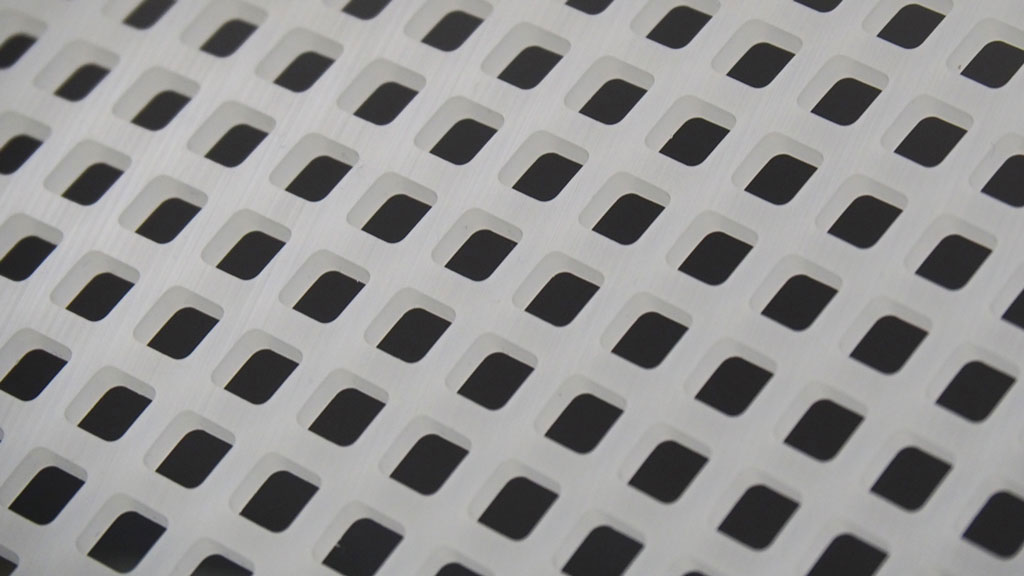

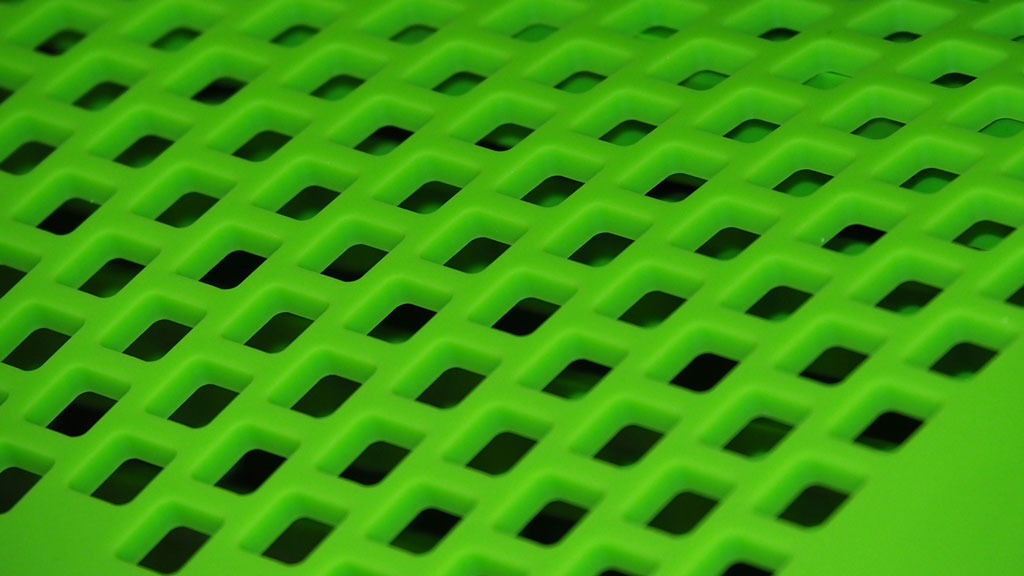

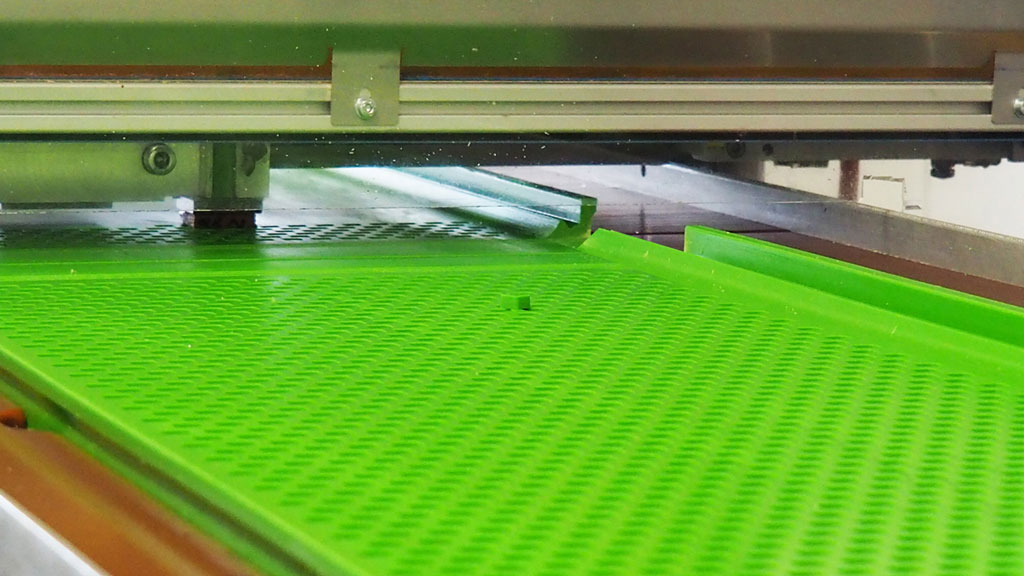

Polyurethane flip-flop screen mats are used in vibration screening machines for the classification of a wide variety of wet or dry bulk materials. In this process, the flexible PU screening mats are vibrated by the machine, individually stretched and relaxed. This leads to the locomotion and screening of the bulk material.

The spectrum of screening tasks ranges classically from sand, gravel, minerals, ores, coal and animal feed to special tasks such as household waste, sewage sludge, incineration slag and a wide variety of recycled goods as secondary raw materials. The worldwide locations, starting from the Arctic Circles to the equator, are also standard for ASMA today.

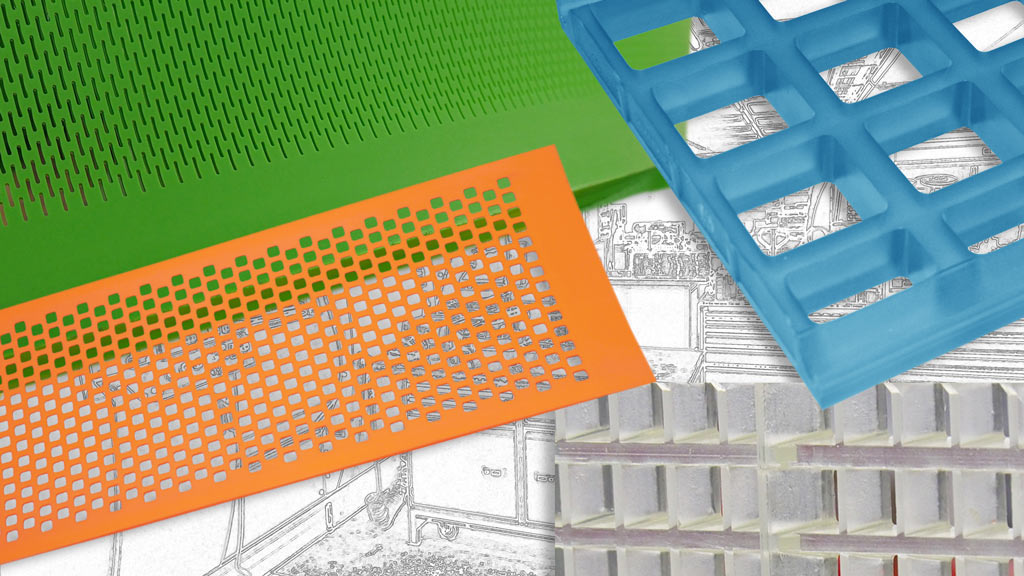

With screening mats made of the different AsmaPrene polyurethane materials and Vulkollan® we cover these requirements such as low-temperature resistance, hydrolysis and microbial resistance, acid and alkali resistance, electrical conductivity and temperature resistance up to 100°C.

The essential quality criteria for good wear resistance and long working life of the screening mats for classic screening applications are the mechanical properties such as tensile strength, tear strength and abrasion.

Thus, the mats are exposed to a strong tensile stress due to the stretching movement. By conveying abrasive media such as sand, gravel, minerals via ores, coal and slag, the surfaces of the mats are rubbed off and incised. The abrasion resistance describes how long a material can withstand this stress. A good tear resistance is responsible for not tearing through the incised areas in the mat.

The polyurethane formulation AsmaScreen has been specially developed for this strong mechanical stress. Various systems were tested, various additives were screened and the recipe trimmed to the highest wear resistance.

In order to achieve the highest quality throughout the entire production chain, the manufacturing process has been standardized by our quality management and is continuously monitored by quality control. In our mechanical laboratory, material samples are checked for tensile and tear resistance, abrasion and hardness.

With screen mats made of AsmaScreen, we set a benchmark on the market in terms of mechanical wear resistance and long working live for these classic screening applications.

More information on the website: